Ceramic Foam

Ceramic foam is a type of porous ceramic material that consists of a network of interconnected ceramic struts forming an open-cell structure. This unique structure gives ceramic foams several advantageous properties, such as low density, high thermal resistance, and good permeability, making them suitable for a variety of applications.

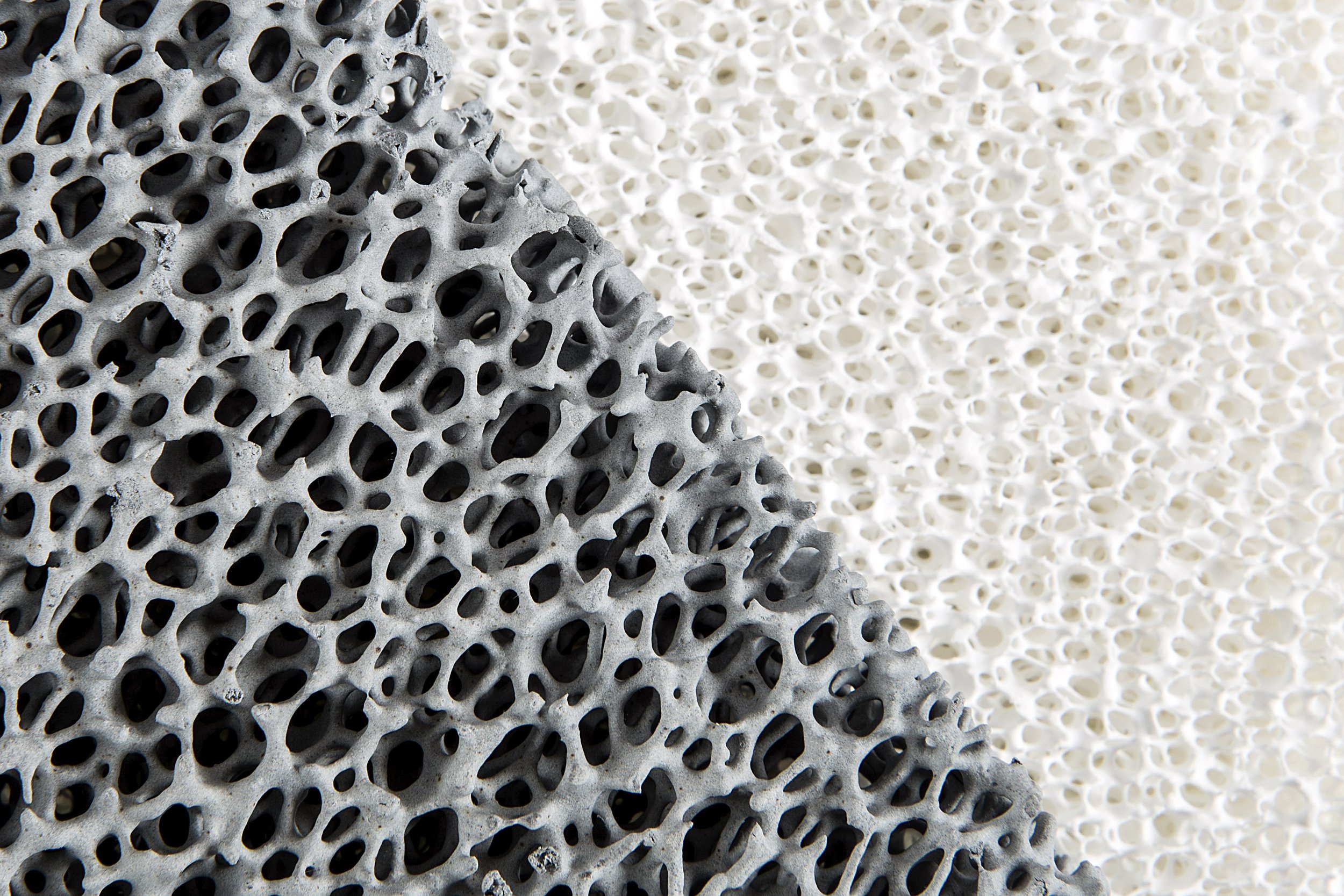

Ceramic foams are a porous ceramic material with a highly interconnected network of holes and cell stems with a cellular structure.

Ceramic foams are produced using reticulated polyurethane foam as the base raw materials. The reticulated polyurethane foam is immersed in a liquid bath that coats the reticulated foam structure. After further processing, the ceramic foam is produced having the same structure of holes and cell stems as the original reticulated foam but without any polyurethane foam remaining.

Ceramic foams can be made from a variety of ceramic materials, including alumina, silicon carbide, zirconia, and others.

The primary application for ceramic foams is for filtration of molten metals to remove impurities and improve the metal product's quality.