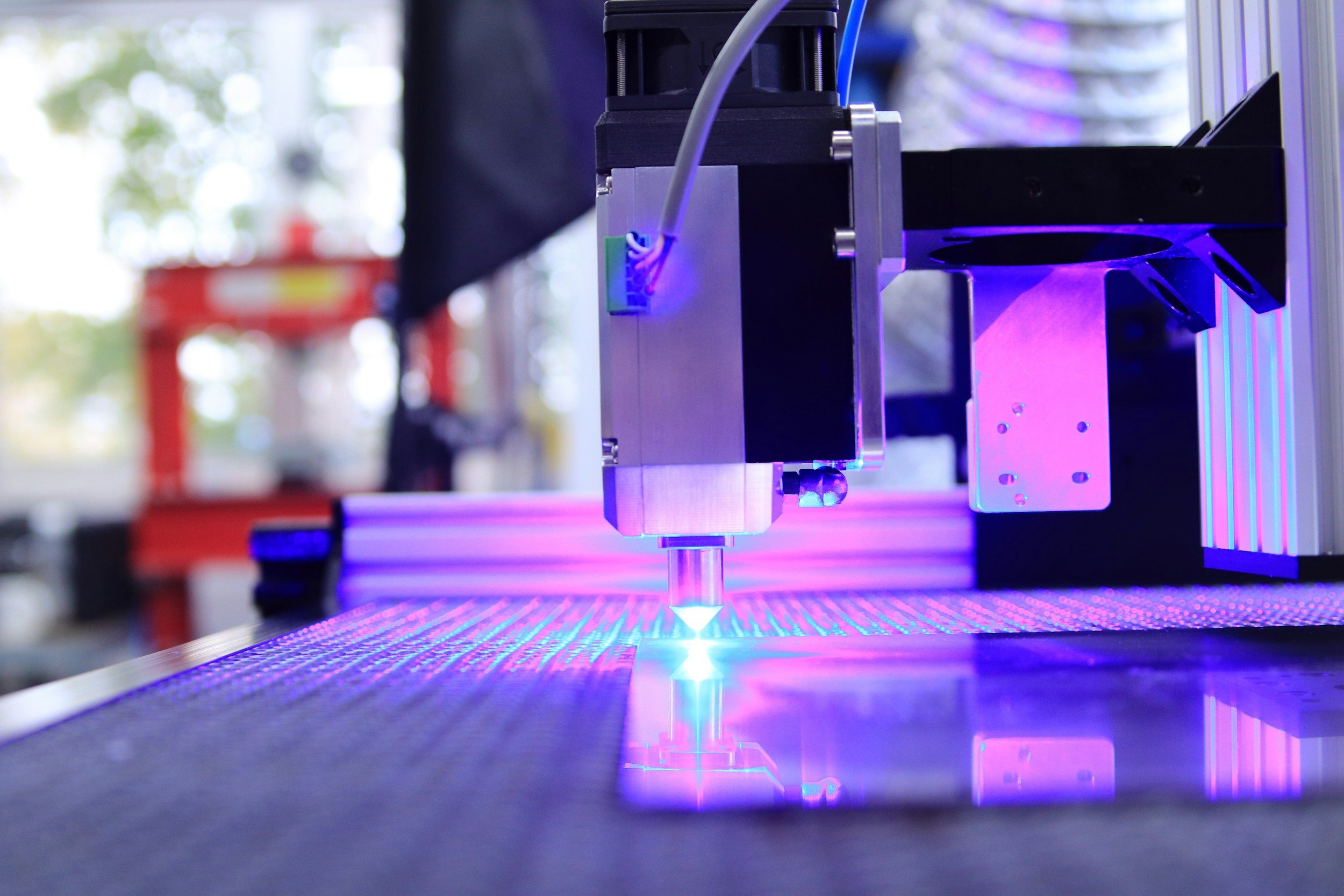

Computer Numerical Control (CNC) & Milling

CNC machining allows us to achieve exceptional precision in shaping and cutting foam. This level of accuracy is crucial for producing components with complex geometries or very tight tolerances required by industries such as automotive, aerospace, and medical devices.

CNC and Milling area highly effective methods for shaping and cutting materials with precision. Polyurethane foam is a versatile material often used in various industries for its lightweight, durable, and moldable properties. These methods can be employed to create intricate designs, prototypes, molds, and final products out of polyurethane foam. CNC and Milling are versatile and efficient methods for machining open-cell foam materials, offering precise control over the final product's shape and dimensions.

Why CNC & Milling

These methods are similar and often described together, but the main difference between CNC machining and Milling is defined by what is moving. If the material is moving, it is considered Milling. If the machine is moving, this is CNC machining.

Specialty foam is machined using CNC (Computer Numerical Control) Milling. Foamtec International's Specialty Foam Division's unique foams are used in applications requiring airflow, cushioning, and absorption properties, such as filtration and padding.

Bring your products' previous design or create a new CAD (Computer-Aided Design). This design will serve as the blueprint for the CNC machine to follow.

CNC and Milling offer several advantages for working with polyurethane foam:

· Precision: CNC machines can achieve high levels of accuracy, ensuring your designs are replicated precisely as intended.

· Complexity: Intricate designs and patterns can be easily milled into polyurethane foam with CNC technology.

· Efficiency: CNC milling is a relatively fast process compared to traditional manual methods, allowing for quicker production times.

· Repeatability: Once a design is programmed, it can be reproduced consistently, making CNC milling ideal for mass production.

CNC and Milling are versatile and efficient methods for shaping polyurethane foam into a wide range of products and components, making them popular in various industries, including aerospace, automotive, packaging, and prototyping.